The global food processing industry is undergoing a rapid transformation. Driven by increasing consumer demand for convenience, safety, and sustainability, food manufacturers are constantly seeking ways to optimize their production lines. Adding to this pressure are rising energy costs and a growing focus on minimizing environmental impact – a landscape heavily influenced by discussions around the energy transition happening worldwide. One often-overlooked but critical component in achieving these goals is the gear motor. These powerful devices are revolutionizing food processing, offering significant improvements in speed, efficiency, and overall productivity.

Food processing facilities face a complex web of challenges. Production needs are escalating – faster throughput is essential to meet consumer expectations and maintain market share. Precise control over processes is paramount, especially in areas like mixing, grinding, and filling, to guarantee product quality and consistency. Furthermore, strict hygiene regulations and stringent safety standards demand equipment that is reliable, easy to clean, and minimizes the risk of contamination. Energy consumption is a major concern, significantly impacting operational costs and contributing to carbon footprints.

Traditionally, food processing relied on simpler motor and gearbox combinations that often suffered from inefficiencies and limitations in speed and precision. The older designs frequently led to increased downtime for maintenance and repairs, adding to the operational expense. However, advancements in gear motor technology are addressing these pain points head-on.

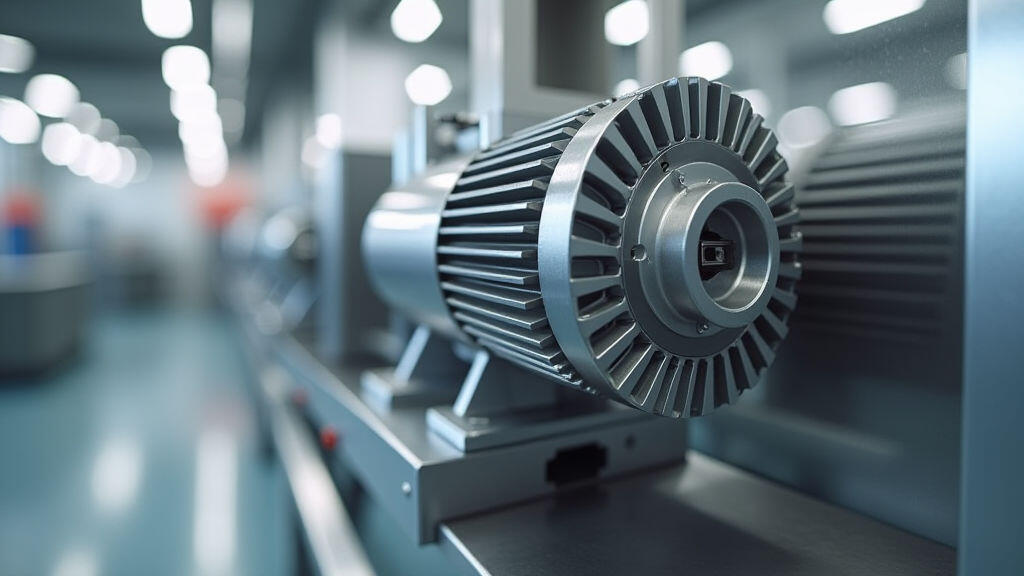

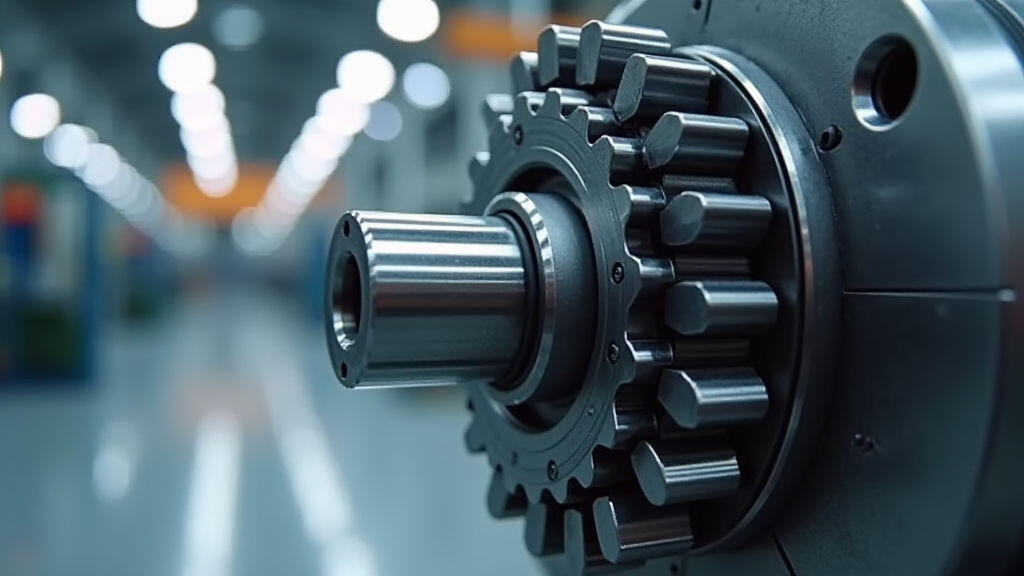

Gear motors combine the benefits of electric motors with gearboxes to achieve high torque and reduced speed. This characteristic makes them exceptionally well-suited for a wide range of food processing applications. Essentially, a gear motor takes the rotational power from an electric motor and reduces its speed while simultaneously increasing its torque. This increased torque translates to greater power for driving heavy-duty equipment.

Here’s a deeper look at why gear motors are becoming the preferred choice:

The versatility of gear motors makes them indispensable across the entire food processing spectrum. Some key applications include:

The demand for energy efficiency is fueling innovation in gear motor technology. Manufacturers are developing gear motors with optimized gear ratios, advanced lubrication systems, and low-friction designs to minimize energy losses. Some notable trends include:

MES-Drive is a global leader in the design and manufacture of high-performance gear motors for the food processing industry. We offer a comprehensive range of gear motors tailored to meet the specific needs of food manufacturers, from small-scale artisanal producers to large-scale industrial plants. Our commitment to innovation and sustainability ensures that our customers benefit from the latest advancements in gear motor technology. MES-Drive gear motors are designed for durability, reliability, and energy efficiency, helping food processors reduce operating costs and minimize their environmental footprint. We provide customized solutions, expert technical support, and a global service network to ensure complete customer satisfaction.

The future of food processing is inextricably linked to energy efficiency and sustainable practices. As the global population continues to grow, the demand for food will increase, placing even greater pressure on the industry to optimize resource utilization and minimize environmental impact.

Gear motors will play a pivotal role in this transformation. Continued innovation in gear motor technology, coupled with the increasing adoption of smart manufacturing solutions, will unlock further opportunities for energy savings, improved productivity, and enhanced product quality. The integration of gear motors with AI-powered predictive maintenance systems will allow food processors to proactively identify and address potential issues before they lead to costly downtime.

The current global focus on the energy transition, coupled with the growing emphasis on sustainable food production, makes gear motors a key enabler of a more efficient and environmentally responsible food processing industry. MES-Drive is committed to leading this evolution, providing innovative solutions that help our customers thrive in a rapidly changing world.

Leave A Reply

Your email address will not be published. Required fiels are marked